Paint Striping

Paint Striping

Paint striping plays a crucial role in maximizing safety, optimizing traffic flow, and enhancing the overall organization of concrete and asphalt surfaces. Whether it’s a parking lot, road, or other paved areas, understanding the importance and process of paint striping can help you ensure efficient and effective striping solutions for your property.

The Importance of Paint Striping

Safety

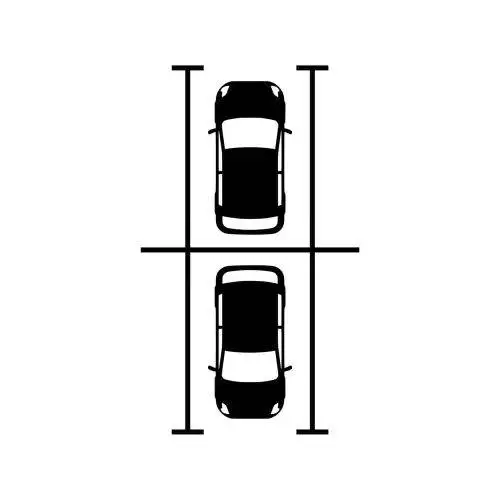

Paint striping provides clear, visible markings that guide drivers, pedestrians, and cyclists, ensuring their safety while navigating parking lots, roads, or pathways. Well-defined lines indicate parking spaces, pedestrian crosswalks, stop bars, and directional arrows, reducing the risk of accidents and enhancing overall safety.

Traffic Flow Optimization

Properly striped surfaces facilitate smooth traffic flow by delineating lanes, indicating turn-only areas, and designating loading zones. This helps drivers navigate easily, reducing congestion and enhancing the efficiency of the space.

Accessibility and Compliance

Paint striping ensures compliance with accessibility guidelines, including the placement of handicap parking spaces, access ramps, and designated paths for individuals with disabilities. It promotes inclusivity and accessibility for all visitors or users of the space.

Paint Striping on Concrete Surfaces

Surface Preparation

Before striping, the concrete surface must be clean and free from debris. Sweeping or power washing is typically done to remove dirt, dust, and loose particles.

Layout Planning

Planning the layout of striping is crucial to ensure optimal space utilization and compliance with regulations. This includes determining parking space sizes, fire lane requirements, traffic flow patterns, and other specific needs.

Marking Application

Using specialized equipment, such as striping machines, experienced professionals apply the appropriate paint to the concrete surface. High-quality traffic paint or thermoplastic materials are commonly used for durability and visibility.

Curing and Drying

After application, the paint needs sufficient time to dry and cure. This typically takes a few hours, depending on environmental conditions. Temporary barriers or cones may be used to prevent traffic or pedestrian interference during this period.

Paint Striping on Asphalt Surfaces

Surface Cleaning

Similar to concrete surfaces, thorough cleaning of the asphalt surface is essential before striping. Sweeping or blowing removes debris, ensuring proper paint adhesion.

Surface Preparation

If necessary, any cracks or potholes in the asphalt should be repaired before striping. This ensures a smooth and even surface for optimal paint application. Ideally, you would stripe right after spraying a layer of sealcoat.

Paint Application

Using specialized striping equipment, professionals apply the paint in the desired layout. High-quality traffic paint, typically latex-based or waterborne, is commonly used for its durability and visibility.

Drying and Curing

After striping, the paint needs time to dry and cure. This process typically takes a few minutes to an hour, depending on environmental conditions. It’s essential to allow sufficient drying time before allowing traffic or pedestrian access.

Consult Professionals for Quality Paint Striping Services

Contact Parking Lots Plus today to learn more about our paint striping services and schedule a consultation. Let us be your trusted partner in enhancing safety, traffic flow, and organization on your concrete and asphalt surfaces.